JJ4805-接线柱的注塑模具设计及成型工艺 下载积分:50 资料编号: JJ4805

2.填写金额:50

3.添加备注,填写资料编号:

会有专人在15分钟内把资料发到您邮箱

备注:如果付款忘记填写资料编号,则发邮件时附带您的交易明细截图即可。

请耐心等待,如超过30分钟还没收到,请联系客服QQ:2363701252

作品描述

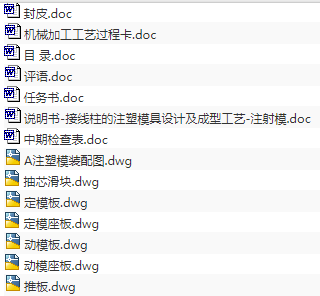

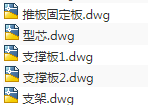

作品包括:

Word版说明书1份,共33页,约12000字

任务书一份

CAD版本图纸,共12张

摘要

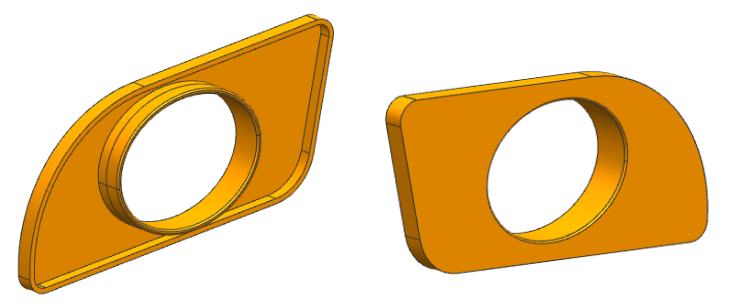

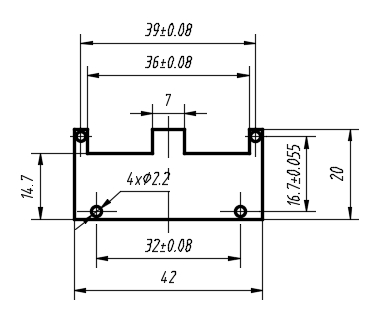

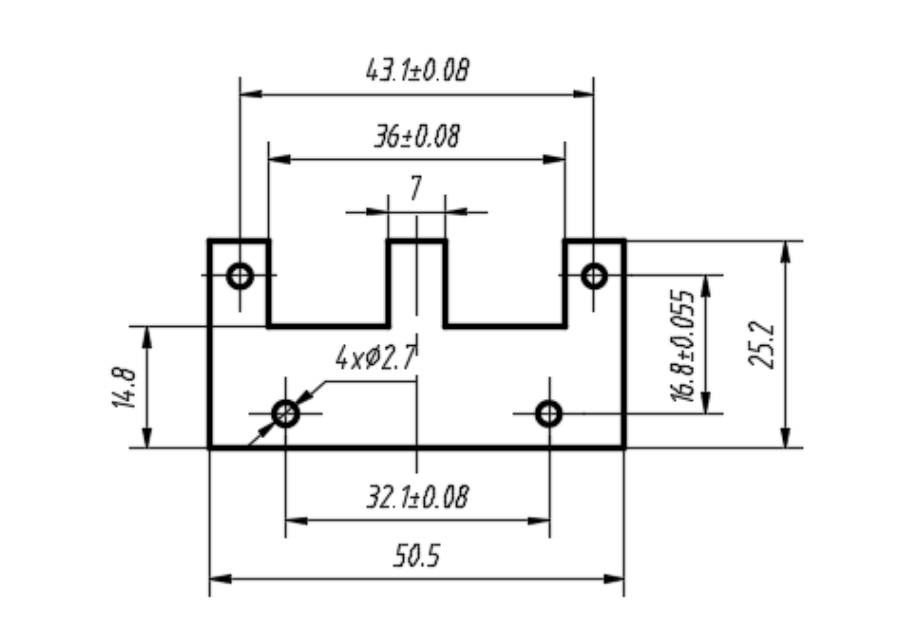

本次设计的是塑料接线柱塑料模具,体现了典型塑料模的设计要求、内容及方向,有一定的设计意义。通过对该模具的设计,加强了设计者对塑料模设计基础知识的理解和运用,为设计更复杂的塑料模具做好了铺垫。

本设计运用塑料模具工艺及模具设计的基础知识,首先分析了产品的性能要求,并选定合适的材料,然后进行了型腔分布设计以及三维立体建模,以选取合适的分型面;最后分析了产品的特征,便于确定模具的设计参数、设计要点及卸件装置。

本设计采用了一模八腔的结构。成型原理如下:首先将松散的粒状或粉末状成型物料从注塑机的料斗送入高温的机筒内加热、熔融、塑化。使之成为黏流溶体,然后再柱塞或螺杆的高压推动下,以很大的流速通过机筒前端的喷射嘴注射进入温度较低的闭合模具中,经过一段时间的保压冷却定型时间后,即可取出注射成型的塑胶接线柱。

成型过程如下:动定模板合模后,由注塑机注射将已加热到熔融状态的材料注射入型腔,经过主流道分流道,充满型腔后,经过一定的冷却保压后,动定模板分离,侧抽芯机构工作,抽芯完成后,压力机推动推板用顶杆推出制件,手动取出即可。

关键字:塑料模、材料、一模八腔、侧抽芯、成型原理、成型过程

目录

第一章塑件及材料的工艺分析············································1

1.1设计任务的原始依据··················································1

1.2塑件的工艺性分析················································2

1.3型腔数目的确定···················································3

第二章浇注系统的设计············································4

2.1确定分型面的位置············································4

2.2确定浇口形式及位置············································4

2.3型腔位置的分布···············································5

2.4主流道设计··························································5

2.5分流道设计··························································7

2.6浇口设计····························································7

第三章成型零部件设计·····················································8

3.1成型零部件的结构设计················································8

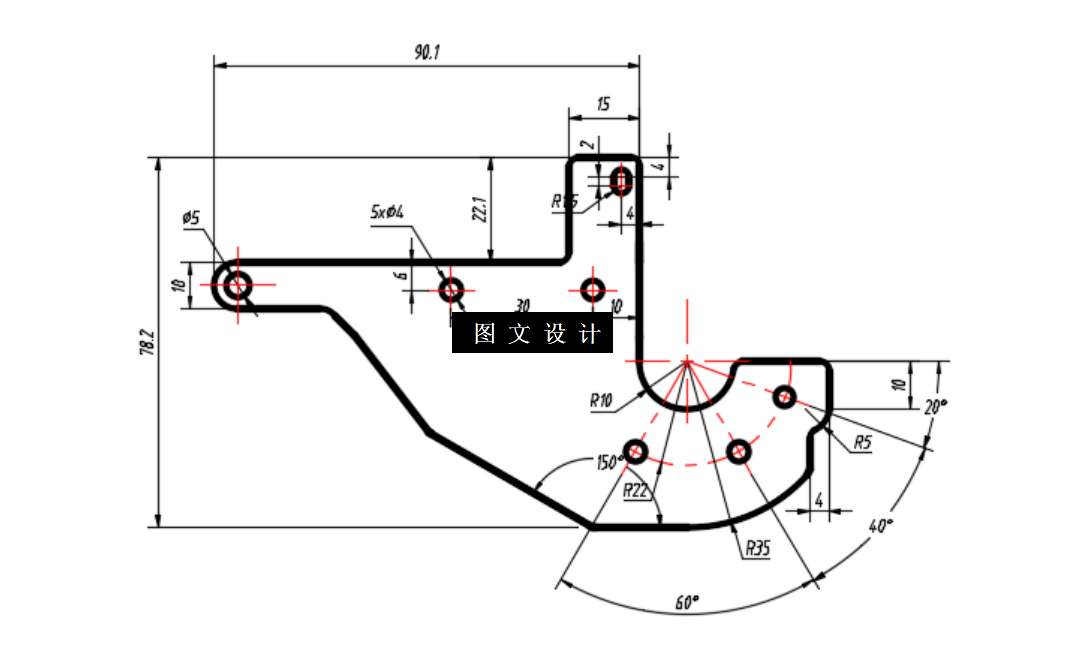

3.2模具侧向分型与抽芯机构的分析与确定··································9

3.3成型零部件尺寸的计算················································11

3.4导向机构设计························································15

第四章推出机构和复位机构的设计··········································15

4.1推出机构的设计·············································15

4.2推杆及复位设计······················································16

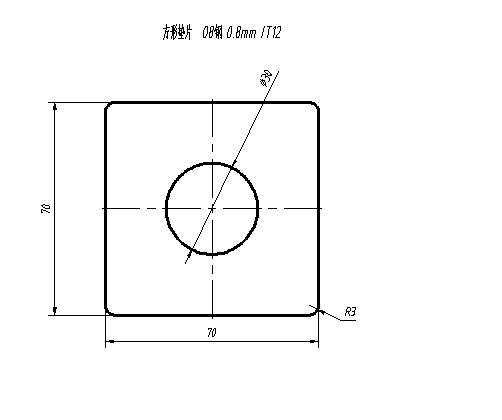

第五章支承与连接零件的设计与选择···························19

第六章冷却系统和排气系统的设计··········································20

6.1冷却系统的设计···············································20

6.2排气系统的设计······················································20

第七章选择注射机和标准模架··············································20

7.1初选注射机···············································21

7.2选择标准模架························································21

7.3注射机的校核·······················································22

第八章结论······························································23

致谢····························································25

参考文献······················································26

温馨提示:

1、题目前面的备注【字母数字编号】为本站整理分类的编号,与课题内容无关,请选题时忽视;

2、若题目上备注三维,则表示文件里包含三维源文件,由于三维组成零件数量较多,为保证预览截图的简洁性,本站将三维文件夹进行了打包。三维及CAD预览截图,均为本站电脑打开软件进行截图的,保证能够打开,下载原件超高清,下载后解压即可;

3、本站所有资源如无特殊说明,都需要本地电脑安装Office2007。图纸软件为AutoCAD,PROE,UG,SolidWorks,CATIA等;

4、本站所有图文资料仅供用户学习参考,不作为任何商用或其他用途;

5、本站不保证下载资源的准确性、安全性和完整性, 不包修改,不支持退换,同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失;

6、 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。